M+FLO-LDH method desalting/removing hard water system process:

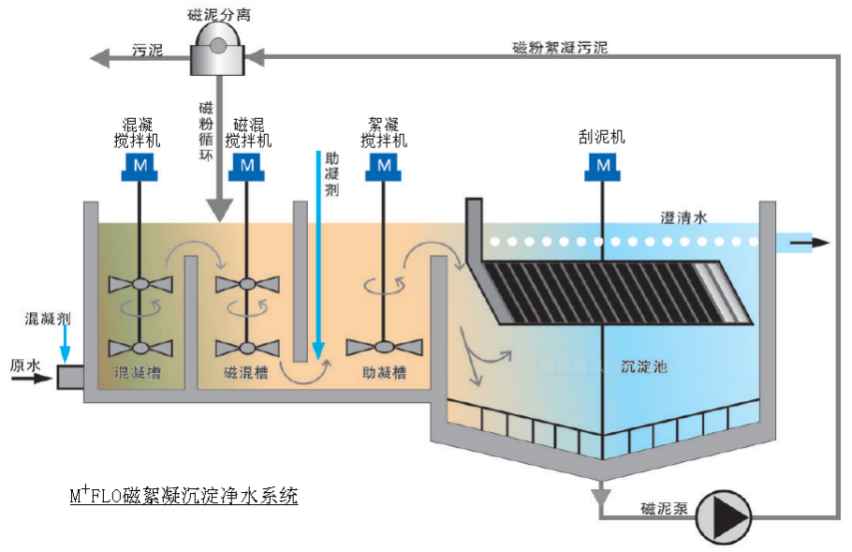

Raw water to DH reaction tank + M+FLO magnetic flocculation system to M+FLO-CO2 dehardening/neutralization magnetic flocculation system to effluent treatment process description: Typical twin tank M+FLO magnetic flocculation + chemical efficient water treatment system. The LDH reactor was added with Ca(OH)2. LDH calcium complex salt was generated by LDH, purified by M+FLO magnetic flocculation system, purified by M+FLO-CO2 dehardening/neutralizing magnetic flocculation system (added CO2), and the PH value was reduced to 6-9. M+FLO sedimentation tank (process flow chart is as follows:) Adding PFS/HFO, magnetic sand and PAM for magnetic flocculation reaction, effectively combining colloidal particles such as LDH calcium double salt to form magnetic floc and precipitate and clarify at high speed to achieve deep purification. The effluent can meet the requirements of industrial water supply treatment or waste water treatment reuse/discharge standards.

M+FLO-LDH desalting mechanism: The mechanism of salt removal is based on the characteristics of interlayer anion exchange of LDHs/ layered compound metal hydroxide. In order to remove certain anion An-, the corresponding compound metal LDH-An- is added, and the reaction occurs under certain conditions such as temperature and PH. Anion in water An- (CO32-, SO42-, NO3-, PO43-, F-, Cl-... Plasma will displace OH- in the LDHs interlayer, forming a double salt precipitate containing An anion, and the solubility product is small. By coupling M+FLO magnetic flocculation precipitation deep water purification system, the effective removal of An-anion salt in water was realized. The general formula of the chemical structure of LDHs is 【M1-X2+MX3+(OH)2】X+(AX/Nn-).MH2O (M2+ is Mg2+, Zn2+, Ni2+, Co2+, Ca2+, Mn2+, etc. M3+ is Fe3+, Cr3+, Fe3+, Sc3+, Al3+, V3+, etc. An- is the interlayer anion CO32-, NO3-, SO42-, PO43-, CrO42-, F-, Cl-, Br-, etc. x is the molar ratio of M3+/ (M2++M3+); m is the molar amount of interlayer water).

Properties and advantages of M+FLO-LDH method: total salt removal rate ~70%, F- < 1.0mg/L, hardness < 50mg/L, suspended matter SS < 3.0mg/L, turbidity < 1.0NTU, and can remove heavy metals and silicon at the same time. The cost of a ton of water treatment is about 1.0-3.5 yuan (related to the amount of salt removal). Compared with the traditional reverse osmosis desalting technology (pre-treatment (turbidization/hard removal) + reverse osmosis membrane RO/DTRO desalting + evaporation crystallization), it has obvious advantages such as simple process/investment province/low operating cost/simple operation and operation, and the generated LDH calcium double salt mud is non-polluting inorganic ettrite minerals, which can be used as mining and metallurgical raw materials, cement raw materials, etc. Or add LDH double salt recycling system to recycle LDH and produce gypsum, which can greatly reduce operating costs & realize resource recycling. Note: M+FLO-LDH technology is not as deep as reverse osmosis RO/DTRO.

Typical applications of M+FLO-LDH: Environmentally friendly & economical salt/hard removal technology, suitable for high salt content (~3000mg/L) and to remove Ca2+, Mg2+, HCO3-, CO32-, SO42-, Cl-, F- and silicon as the target of removal of water (can also deeply remove heavy metals, fluorine, arsenic and other pollutants), effluent turbidity can be less than 1.0NTU.

Industrial wastewater desalination/removal of hard standard discharge or reuse, the main target removal substances are Cl-, SO42-, Ca2+, Mg2+, total salt, etc.

After treatment of industrial recycled water effluent, the main target removal substances are Cl-, SO42-, Ca2+, Mg2+, TP, silicon, etc.

The raw water of industrial water supply station removes Cl-, SO42-, Ca2+, Mg2+ and silicon.

Typical case: Qitaihe Coal mine wastewater demineralization/dehardening treatment process: pre-settling/regulating pool +M+FLO-LDH/CO2 demineralization/dehardening/neutralization water purification system. Pre-settling/regulating tank water quality: SS/281, Ca2+/483, Mg2+/92, HCO3-/81, SO42-/1510, Cl-/110, F-/2.7, Silicon /223, total salt /2435mg/L, Requirements after treatment to meet the reuse specifications (TDS/1600mg/L, hardness /100mg/L, silicon /20mg/L, F-/1.0mg/L, SS/10mg/L). After the system was put into operation, the effluent water quality was stable and up to standard. The measured values were :TDS/1430mg/L, hardness /55mg/L, silicon /5.1mg/L, F-/0.9mg/L, SS/4L.

换一换

换一换