In the open circulating cooling water system, the concentrations of Ca2+, HCO3-, SO42-, Mg2+, SiO32- ions and harmful substances such as suspended matter, biological colloid, organic matter and oil will continue to rise with the evaporation of circulating water and cause problems such as ① scaling and deposition ② corrosion ③ microbial (bacteria, fungi and algae) breeding and reproduction. The solution is to reduce the hardness/reduce the concentration of corrosive ions (such as Cl-)/reduce the organic and microbial content. The concentration is usually reduced by blowdown/simultaneous water refill and the harmful substances are controlled within the specified allowable limits, see the annex "Industrial circulating cooling Water treatment design Code" GB/T50050-2007.

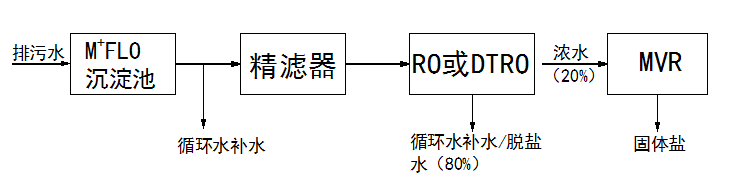

<p sAt present, the basic process of recycling sewage treatment and reuse is: chemical removal of hard coagulation and clarification → mechanical filtration → desalination. General pre-treatment of reverse osmosis membrane RO is flocculation clarification (effluent turbidity < 10NTU)/mechanical filtration (effluent turbidity < 3NTU)/activated carbon filtration or ultrafiltration membrane (effluent turbidity < 1NTU). The precipitated salt formed by chemical precipitation method is in a tiny colloidal state, which is not easy to condense and has poor settlement. The separation effect of conventional mechanical stirring clarifier or high-efficiency sedimentation tank is poor, and the effluent is easy to exceed the standard. M+FLO plus magnetic flocculation water purification system is a revolutionary alternative to conventional flocculation clarifier such as high efficiency sedimentation tank, which can deeply remove small suspended matter, phosphorus, grease, colloids and microbial algae, etc. Combined with Ca (OH) 2, Na2CO3 or Na2AlO3, it can remove calcium, magnesium, silicon, heavy metals or reduce SO42-+Cl- content. Free chlorine can be removed by adding powdered activated carbon. The treatment efficiency of M+FLO is far better than that of sand filtration/microfiltration/fiber turntable/air flotation, etc., and other indicators (except salt content) of effluent water hardness < 0.3mmol/L and SS < 3mg/L are far better than the allowable limit of circulating water recharge. It can directly recharge the circulating cooling water system or carry out RO/DTRO desalting treatment. The reclaimed fresh water can be used to recharge the circulating water (dilute the salt concentration/reduce the conductivity).

M+FLO plus magnetic flocculation technology advantages:

① Excellent depth removal/effluent water quality, greatly reduce the post-processing load ② short residence time of the system, small footprint, low project investment ④ low power consumption, save medicine ⑤ intelligent automatic control, no personnel on duty.

Attachment:

M+FLO plus magnetic flocculation technology advantages:

|

Project |

Unit |

Water quality standards |

Project |

Unit |

Water quality standards |

|

SS |

mg/L |

<20 <10(Plate, warped tube and spiral plate) |

Calcium hardness + methyl orange alkalinity |

mg/L The value is CaCO3 |

≤1100 (RST≥3.3) Calcium hardness < 200 (water side > 70℃) |

|

Turbidity |

NTU |

<20 <10(Plate, warped tube and spiral plate) |

Silicic acid |

mg/L The value is SiO2 |

≤175 |

|

Cl- |

mg/L |

≤1000(Carbon steel, stainless steel/pipe) ≤700(Carbon steel, stainless steel/pipe) |

Mg2+×SiO2 |

mg/L Mg2+ is calculated in CaCO3 |

≤5000 (pH≤8.5时) |

|

SO42-+Cl- |

mg/L |

≤2500 |

Free chlorine |

mg/L |

0.2-1.0 |

|

Conductivity |

µs/cm |

<3000 |

NH3-N |

mg/L |

≤10 |

|

pH |

6.8-9.5 |

petroleum |

mg/L |

≤5(Non-refinery) ≤10(Oil refining) |

|

|

Total Fe |

mg/L |

≤1.0 |

CODcr |

mg/L |

≤100 |

|

Cu2+ |

mg/L |

≤0.1 |

The number of aerobic bacteria |

PCS/mL |

<5×105 |

|

Ca2+ |

mg/L |

>30(Corrosion inhibition requirement) <200(Scale inhibition requirement) |

Slime content |

mL/m³ |

<4 |

换一换

换一换