The tail water of the sewage plant will still contain high salt, hardness, alkalinity, phosphate, suspended matter, organic matter, bacteria and heavy metals and other harmful substances, which will be used in industry such as circulating water and need to be further treated to further remove ① hardness, alkalinity, phosphate, suspended matter colloid ② dissolved organic matter ③ inorganic salt ④ bacteria and algae. The most commonly used process is lime/soda ash coagulation precipitation purification treatment, which can effectively reduce hardness, alkalinity, phosphate, suspended matter, heavy metals, etc. (and can kill bacteria), and also has a certain removal capacity for total organic matter and silicon, fluorine, free chlorine, etc. The treated water can be used as industrial circulating water replenishment or continued reverse osmosis RO/DTRO desalting treatment to produce desalted water (high concentration rate circulating water replenishment). Attached is "Industrial circulating cooling water treatment design Code" GB/T50050-2007.

The cooling tower of circulating water system has the function of denitrification (1) to blow away free ammonia (2) biological nitrification. When ammonia nitrogen is < 3.0mg/L, the cooling tower is used to remove ammonia nitrogen, and the ammonia nitrogen in circulating water can be stabilized at 1.0mg/L (up to the standard), but when ammonia nitrogen is > 3.0mg/L, it is difficult to reach the standard only by the cooling tower of circulating water.

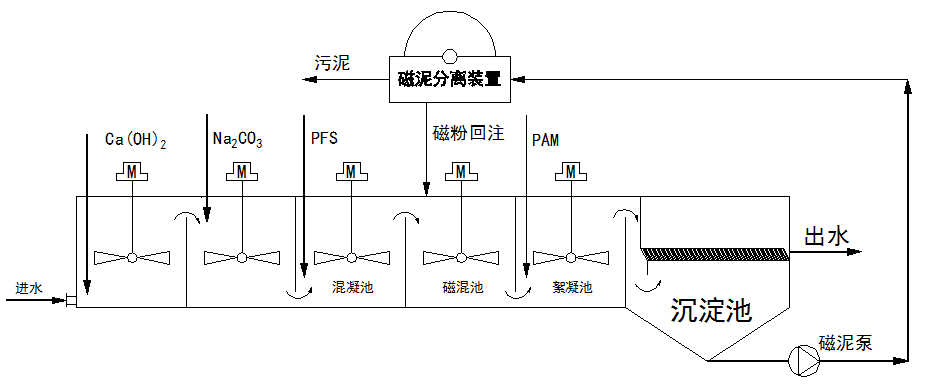

The conventional lime/soda ash flocculation precipitator is vulnerable to the impact of water quality or water quantity changes, and the effluent water quality is unstable and often exceeds the standard. Use M+FLO plus magnetic flocculation precipitation technology to replace or transform the conventional flocculation precipitation clarifier (flow chart is as follows).

The introduction of magnetic powder in the lime coagulation process (magnetic powder is recycled in the system), can form a larger density and volume of magnetic floc, not only several times (3-5 times) to increase the processing capacity, but also greatly strengthen the adsorption of fine particles (including colloids, bacteria, etc.), can greatly reduce the salt content, hardness, alkalinity, heavy metals, etc. At the same time, it can deeply remove small suspended matter, phosphorus, grease, colloids and microbial algae. The effluent index of M+FLO magnetic flocculation sedimentation tank is excellent and stable, and it can withstand the impact of water quality and quantity changes. The effluent water quality is far better than the circulating water replenishment index, and the turbidity can reach < 1NTU (conventional dual-process combination of flocculation precipitation and filter tank). For those requiring further desalting treatment, the load of the pre-filtration process is greatly reduced. The M+FLO effluent can be directly replenishment to the circulating cooling water system or continue the reverse osmosis RO/DTRO desalination process.

M+FLO lime coagulation/water treatment effect

Project | Total alkalinity mg/L | Full hardness mg/L | Calcium hardness mg/L | Magnesium hardness mg/L | SiO2 mg/L | Total phosphorus mg/L | Oils mg/L | SS mg/L | turbidity NTU | CODcr mg/L | BOD5 mg/L | NH3-N mg/L | strain /mL |

Raw water | 630 | 880 | 500 | 380 | 11 | 0.5 | 2.1 | 23 | 11 | 47 | 5 | 4.8 | 7.0×104 |

purified water | 120 | 140 | 105 | 35 | 2.7 | 0.05 | 0.1 | 4.0 | 0.8 | 31 | 4.2 | 4.7 | 930 |

Attachment:

Water quality index of reclaimed industrial circulating water.

Project | pH | turbidity NTU | Conductivity µs/cm | Total hardness mg/L | Total alkalinity mg/L | Ca2+ mg/L | Cl- mg/L | Total phosphorus mg/LP | CODcr mg/L | NH3-N mg/L | Bacterial population /mL |

Allowable values (Class I) | 6-9 | <5 | <300 | <200 The value is CaCO3 | <150 The value is CaCO3 | <36 | <300,stainless steel≤100 | <1.0 | <40 | <1.0 | winter<5.0×105 Summer<1.0×105 |

换一换

换一换