The Yellow River water conductivity of 900-1110µs/cm (twice that of groundwater), salt content of 700mg/L (twice that of groundwater), organic content of 3-5mg/L (1mg/L of groundwater), turbidity, etc. (especially SO42-, Cl-, Na+, etc.) are much higher than that of groundwater. The water quality data collected are as follows:

Project | Content(mg/L) | Project | Content(mg/L) | Project | Content(mg/L) | Project | Content(mg/L) |

K+Na- | 130 | Cl- | 105 | pH | 8.0 | TFe | <0.04 |

Ca2+ | 61.7 | SO42- | 214 | H2SiO3 | 8.69 | NH4+ | 0.3 |

Mg2+ | 35.2 | HCO3- | 245 | Turbidity | <6 | NO3- | 19.37 |

TDS | 725 | Colloidal silicon | 49.6 | Total bacterial count | 100 | NO2- | 0.25 |

SS | 31 | Dissolved silicon | 7.2 | Total hardness | 346.90 | Total coliform | 100 |

COD-Mn | 4.2 | Electric conductivity | 907µs/cm | Total alkalinity | 218.54 | Total phosphorus | 0.7 |

CO32- | 5.40 | TOC | 5.6 | ||||

Yellow River water treatment is used as industrial water, the main treatment processes are: flocculation clarification → mechanical filtration →RO membrane desalination. Generally, the pre-treatment of reverse osmosis membrane RO is flocculation clarification (effluent turbidity < 10NTU)/mechanical filtration (effluent turbidity < 3NTU)/activated carbon filtration or ultrafiltration membrane (effluent turbidity < 1NTU), usually the influent index of RO requires turbidity < 1NTU/ free chlorine < 0.1mg/L.

At present, the surface water treatment for industrial use of high-efficiency sedimentation tank for pre-purification treatment, not only occupies a large area, large drug consumption, and the effluent effect is poor, especially in summer, raw water turbidity, algae reproduction is easy to cause the effluent exceeded, resulting in ultrafiltration membrane, reverse osmosis membrane fouling.

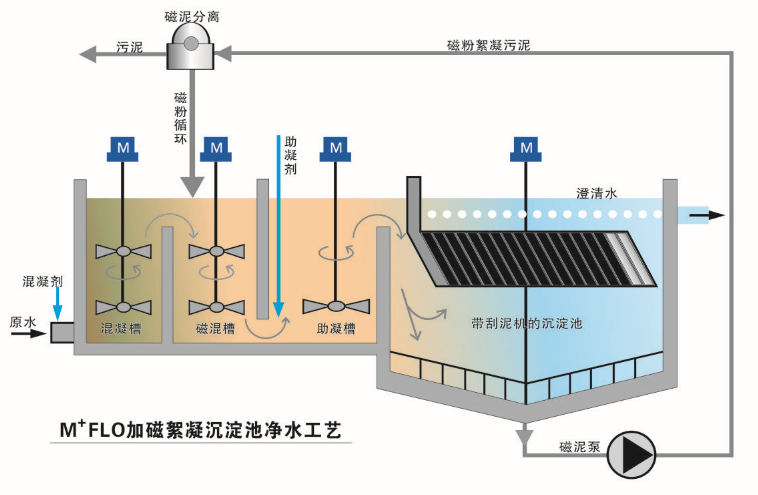

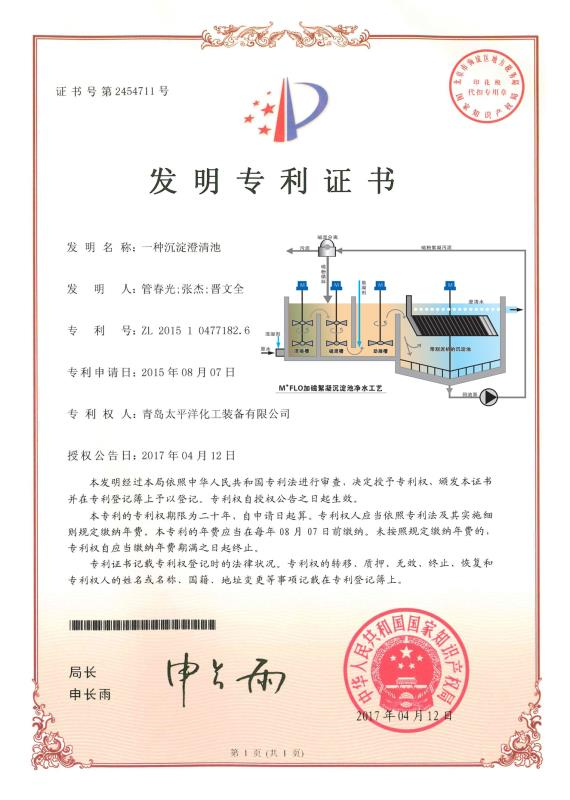

M+FLO plus magnetic flocculation water purification system is a revolutionary upgrade of conventional flocculation clarifier such as high efficiency sedimentation tank (with standard flow chart), its treatment efficiency is far better than coagulation sedimentation/sand filtration/microfiltration/fiber turntable/air float, etc., can deeply remove small suspended matter, phosphorus, grease, colloids and microbial algae. The effluent turbidity is < 1NTU, and other indicators are far better than the inlet water quality standard of RO, which can greatly reduce the load of the post-sequence fine filter. The combination of Ca (OH) 2 and Na2CO3 can remove the hardness of calcium and magnesium, silicon and heavy metals. The effluent from the M+FLO sedimentation tank can be directly used to recharge the circulating cooling water system or to continue the reverse osmosis membrane RO (circulating water replenishment/fresh water) or to continue the desalination treatment such as EDI (softened water for boiler) (see the treatment process below).

换一换

换一换