The phosphorus content of wastewater produced by pharmaceutical, starch processing, wine industry, slaughtering and other industries is often much higher than that of most industrial wastewater, and the composition is complex, including phosphorus, hypophosphorous, phosphorus and organophosphorus. Usually, the main process of the treatment of such wastewater is: AAO biological nitrogen and phosphorus removal → chemical phosphorus removal/high-density sedimentation tank + filter, phosphorus containing wastewater after biochemical treatment, most of the organophosphorus, metaphosphorus, polyphosphorus, etc. can be absorbed by microorganisms and discharged with microbial sludge, but often there will be some residual, and some are decomposed into small phosphorus molecules. Chemical phosphorus removal agents such as aluminum or iron salt are added to the effluent after biochemical treatment. Aluminum AI3+ ion or iron ion Fe3+ combine with phosphoric acid to convert dissolved phosphorus into particulate phosphorus precipitation. Phosphorus removal by metal salt follows the following three steps:

1.Hydrolysis reaction: AI3++H20→AI(OH)3;

2.Surface complexation reaction: AIOO-H+OH-PO3→AIOO-PO3+H2O(surface active site, oxygen-containing functional group covalently binds with phosphate ions);

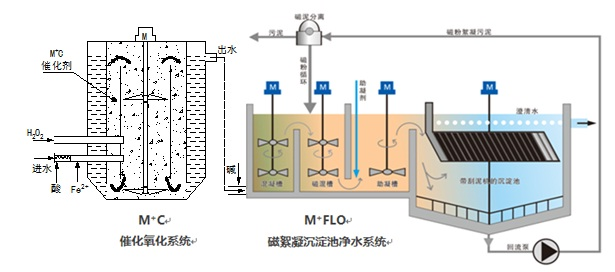

3.Collision and combination:AI(OH)3→AI2(OH)6→ AIn(OH)3n,that is, flocculation occurs at the same time as the formation of granular phosphorus, and PAM flocculant is added to form a large flocculation of suspended particles (including colloidal particles of aluminum phosphate or iron phosphate) through electric neutralization and bridging adsorption, and then it is separated by sedimentation tank and filtered by filter. But the amount of phosphorus in the water often still exceeds the standard. First, dissolved phosphorus such as organophosphorus and hypophosphorous cannot combine with metal ions to form insoluble phosphorus particles; The second is that the precipitation salt of aluminum phosphate or iron phosphate generated by chemical phosphorus removal is colloidal particles, extremely slight and fine, not easy to be combined and precipitated by floc, and can penetrate the filter layer. For the deep phosphorus removal of organophosphorus and hypophosphorous wastewater, the deep water purification system of M+C catalytic oxidation +M+FLO plus magnetic coagulation sedimentation tank should be selected (see the system flow chart below).

The wastewater was first catalyzed by M+C/IRFR fluidized reactor to convert organophosphorus and hypophosphorous into phosphates, and then entered M+FLO magnetic flocculation sedimentation tank system (and added flocculant PAM) for purification treatment. M+FLO precipitation can efficiently and deeply remove particulate phosphorus and SS in water. The mechanism is that magnetic powder is introduced in the flocculation reaction, which can form magnetic floc with larger volume and density, which greatly strengthens the flocculation effect. It can effectively adsorb fine colloidal particles and rapidly settle with the magnetic floc, so that the water can deeply remove the insoluble particles such as TP and SS. It can achieve stable effluent TP<0.1mg/L, SS<5mg/L, and no need to set a post-sequence filter (depth treatment was originally designed for the combination of high-density sedimentation tank and filter tank, just simply transform the high-density sedimentation tank into M+FLO sedimentation tank, no need to run the filter tank).

Typical application case - The second phase of Qingtongxia Industrial Wastewater treatment Project of Hualu Chemical Company produces 5000 tons of industrial wastewater every day, with phosphorus content TP=80mg/L, ammonia nitrogen =200mg/L, COD=1300mg/L,SS=390mg/L. The main process of sewage treatment is regulation tank → primary sedimentation tank → anaerobic tank → anoxic tank → aerobic tank → secondary sedimentation tank →M+C catalytic oxidation + M+FLO sedimentation tank (patented technology of Qingdao Pacific Chemical Equipment Company). After treatment, the effluent phosphorus content TP<0.3mg/L, ammonia nitrogen <5mg/L. COD<50mg/L,SS<8mg/L(Emission standard: Class A).

换一换

换一换